R-VALUES, MISLEADING? OUR OPINION

R-values are the received wisdom for evaluating thermal insulation efficiency, but — as is often true of received wisdom — they don’t tell the whole story. In fact, they might even be misleading, which matters when governments around the world are setting ambitious targets for carbon reduction, and fit-for-purpose thermal insulation has never been more important.

An imperfect ratio

There are several reasons why R-values alone cannot provide a true and accurate measurement of how modern-day insulation should be chosen. The first is the formula on which the R-value calculation is based — the thickness of the insulation divided by its thermal conductivity. It’s a simple measure, according to which the thicker the insulation, the higher the resulting R-value and — supposedly — the better the product’s performance. It’s a simple, but imperfect, ratio, as I will explain. The second reason is that today’s thin-wall thermal insulation materials are by many measures equally, if not more, efficient than their bulkier competitors.

This case to look beyond R-values alone becomes stronger when you consider that the base calculation on which they are based is arguably outdated. It has been in place — unmodified and often unquestioned — for decades, and dates from the time when fibre-based products dominated the market. Due to the manufacturing process, these generally had a minimum thickness of 1” — with the result that building codes in many countries fail to take into account the advent of thin-wall materials, and so do not reflect the current state of insulation technology.

Missing the point

In my view, basing insulation purchasing decisions on R-values alone misses the point about why we insulate pipework in the first place — which is to reduce heat loss (or heat gain in cold-side applications). Change the focus, evaluate insulation performance by how effectively it performs these critical functions, and some interesting results emerge, as the following evaluations — all conducted under ISO 12241:2008 — demonstrate.

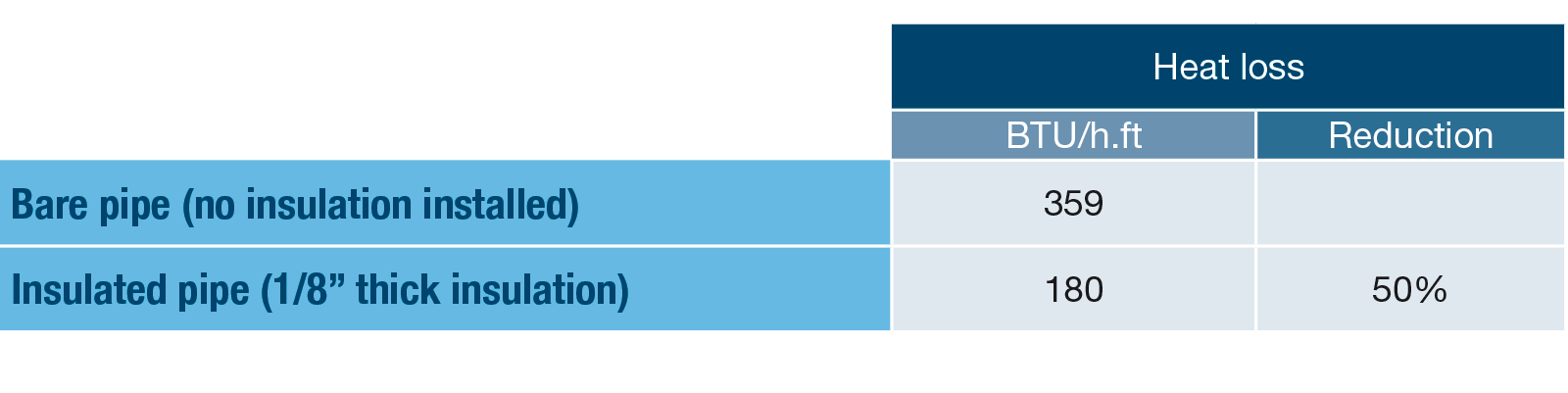

Consider a 2”NB pipe running at a line temperature of 302°F, with ambient conditions at 77 °F. Uninsulated, heat loss will be 359 BTU/h.ft, but install modern thin-wall insulation just 1/8” thick and heat loss falls dramatically — by 50%.

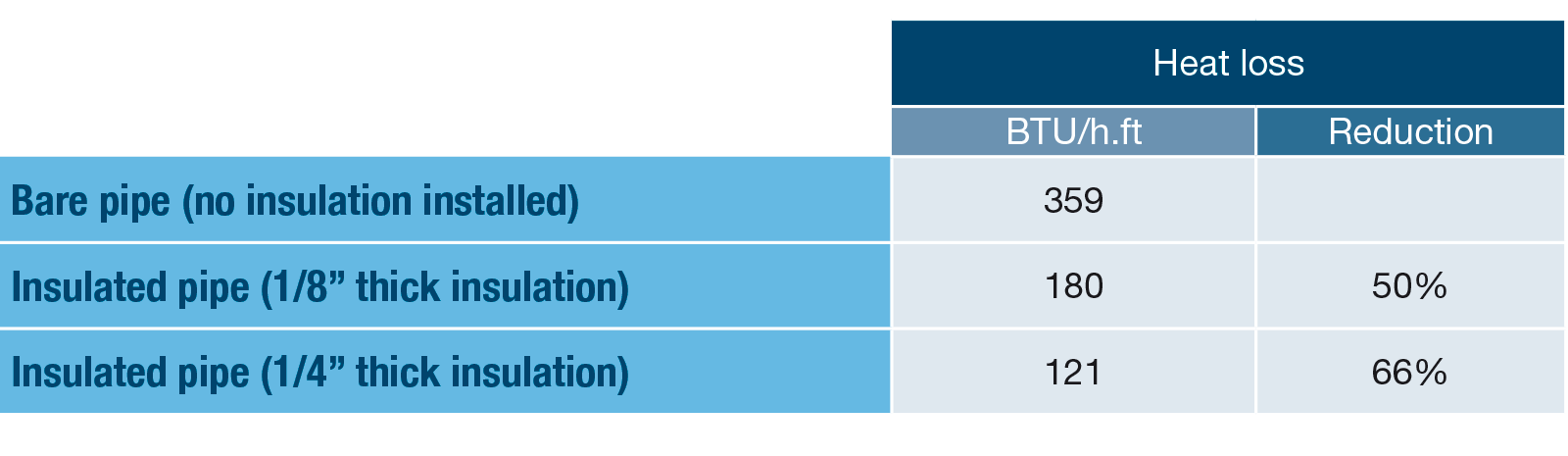

Increase the insulation thickness to ¼” and these are the results:

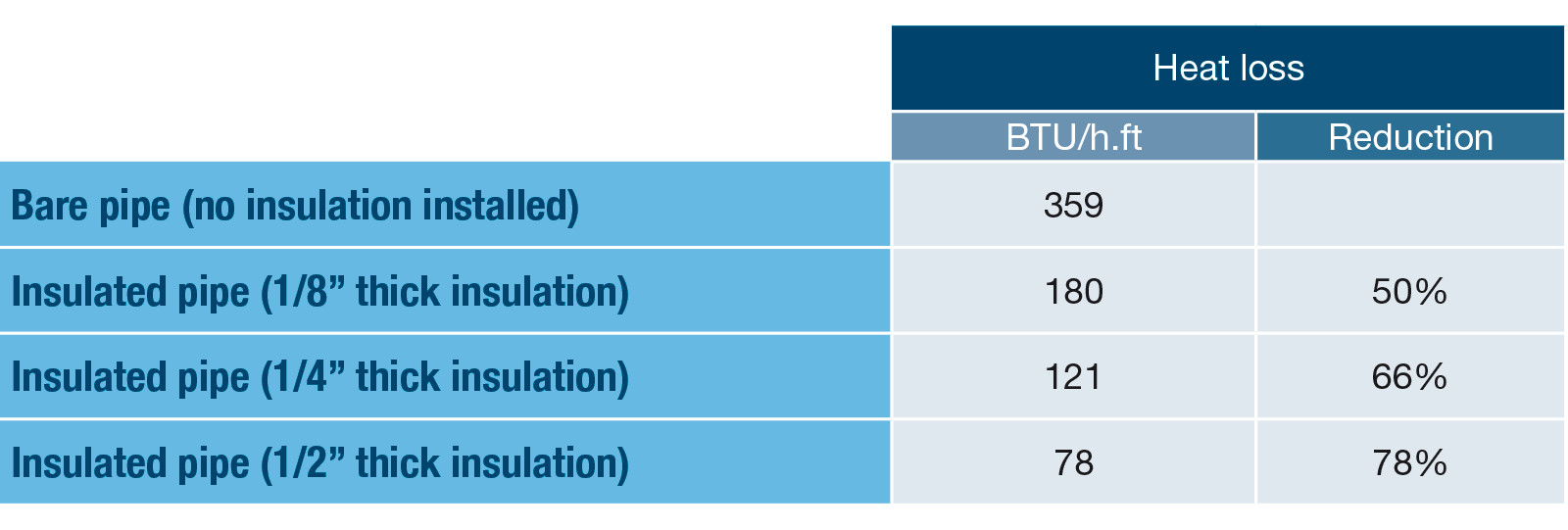

Now increase the insulation thickness to ½”:

R values based on k value of 0.284 Btu.in/h.ft2 °F @302 °F

More bang for your insulation buck

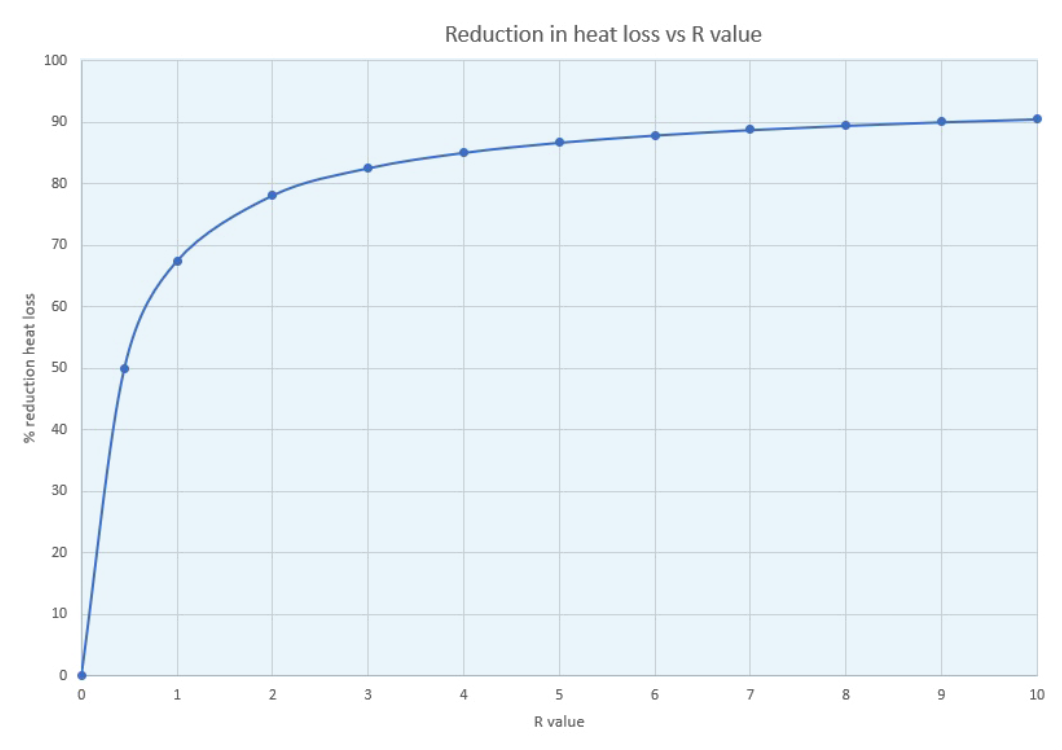

What this shows is that just ½” of insulation, with an R-value of 2.03, reduces heat loss by 78 %. Apply it to our example — the 2”NB pipe running at 302°F — and compare its performance with insulation with other R-values and the results are eye-opening:

Open up to closed-cell insulation

Regarding R-values as the ‘be-all and end-all’ also ignores another key factor that contributes to insulation performance — whether the material chosen is of closed- or open-cell construction. This is important, because closed-cell products offer considerable benefits over open-cell products in several key areas:

Longevity and minimal maintenance: While reduction of heat loss in hot systems (heat gain in cold) is of primary importance, longevity of the insulation material is equally important — perhaps more — and can have a large influence over service lifetime. Closed-cell insulation requires minimal maintenance, providing further significant cost-savings over an extended service-life.

Moisture resistance: Moisture absorption of just 4% can degrade insulation performance by up to 70%. Open-cell materials naturally absorb moisture and rely on an outer cladding to prevent such ingress. In practice, ensuring continuity of such vapor barriers both during installation and over the lifetime of the insulation is difficult, and breakdown of the materials and corrosion under insulation (CUI) is common. By their very nature, closed-cell materials, on the other hand, do not absorb moisture or need an outer vapor barrier, and so do not contribute to CUI.

Wall thickness: Closed-cell products are supplied and readily available from ¼” thick, and so can insulate pipework in tight spaces — something difficult, even impossible, to insulate with thicker insulation — and the overall space allocated for pipe racks can be designed on smaller footprints.

Atmospheric contamination: Finally, closed-cell materials generally do not disintegrate or release any particles or pollutants into the work environment. In contrast, traditional thicker insulation products may release fibers and other pollutants to the atmosphere.

In summary, it pays in many ways to remember what the insulation is actually there for — reducing heat loss or gain. Ignore the received wisdom, cast off the ‘R-value blinkers’ and take a more holistic view of insulation performance.